For a new client in the UK FB Group has fabricated and supplied a Turbine baseplate frame. Scope included detailed engineering, fabrication, machining, painting, packing and transport to the UK. The baseplate with a total weight of 48.000 kg was delivered in time and in accordance with the highest quality standards by DNV Maritime. Thanks to all who contributed to this successful project completion.

View photosSupply of Seal Gas Conditioning Skids

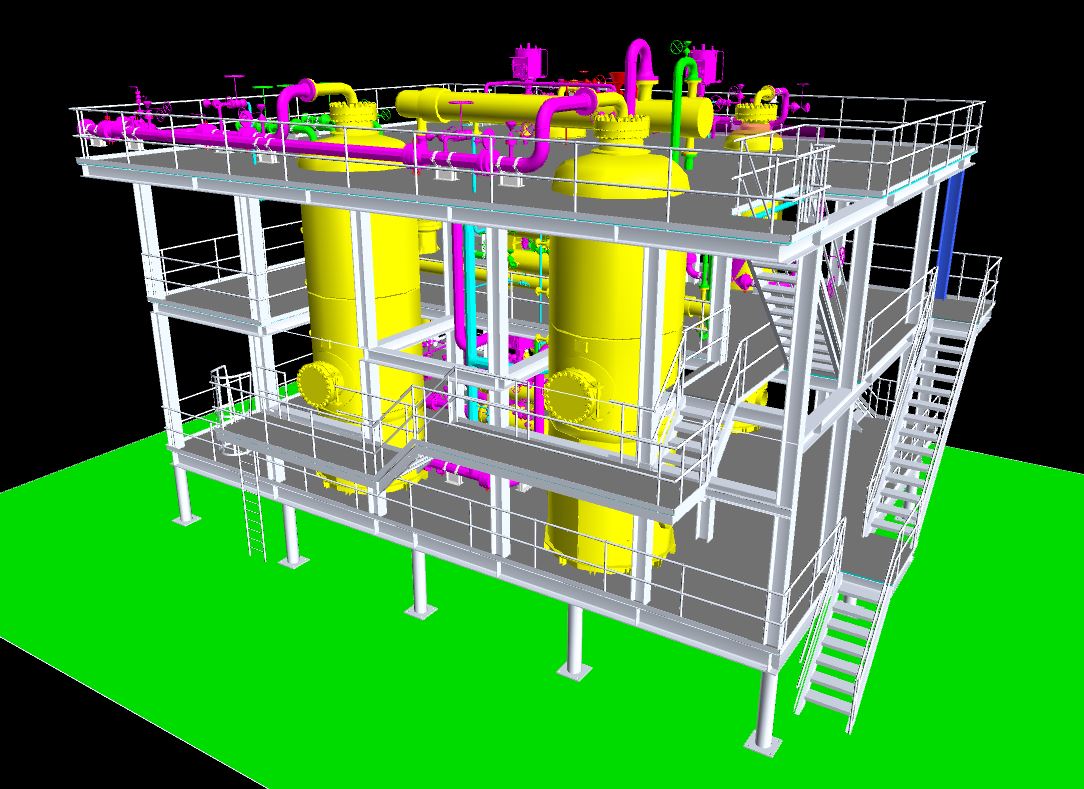

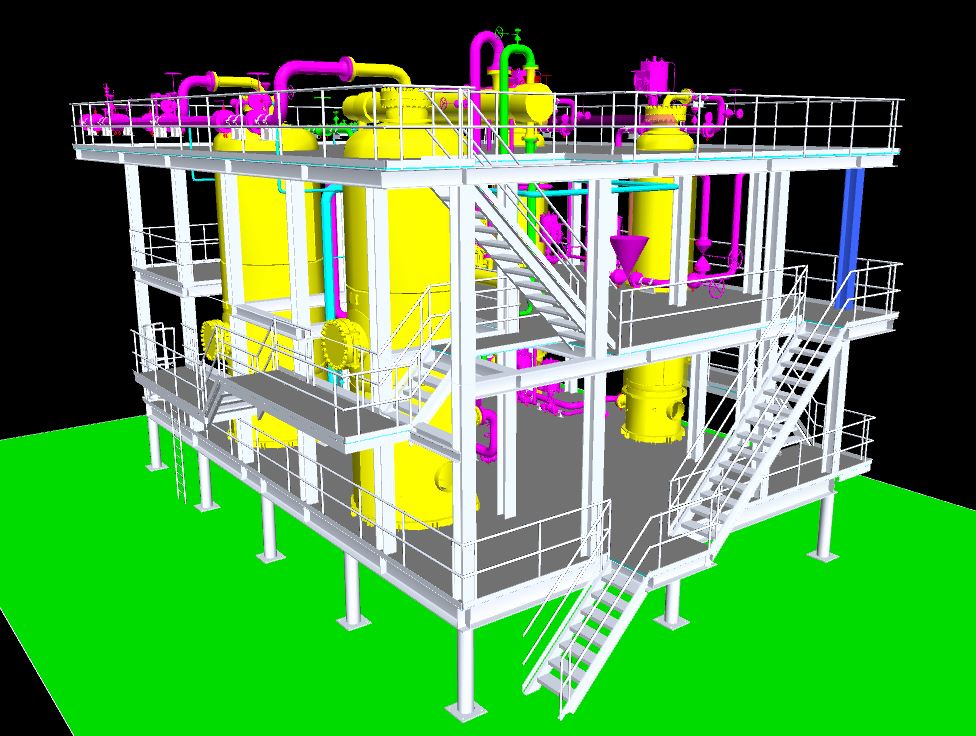

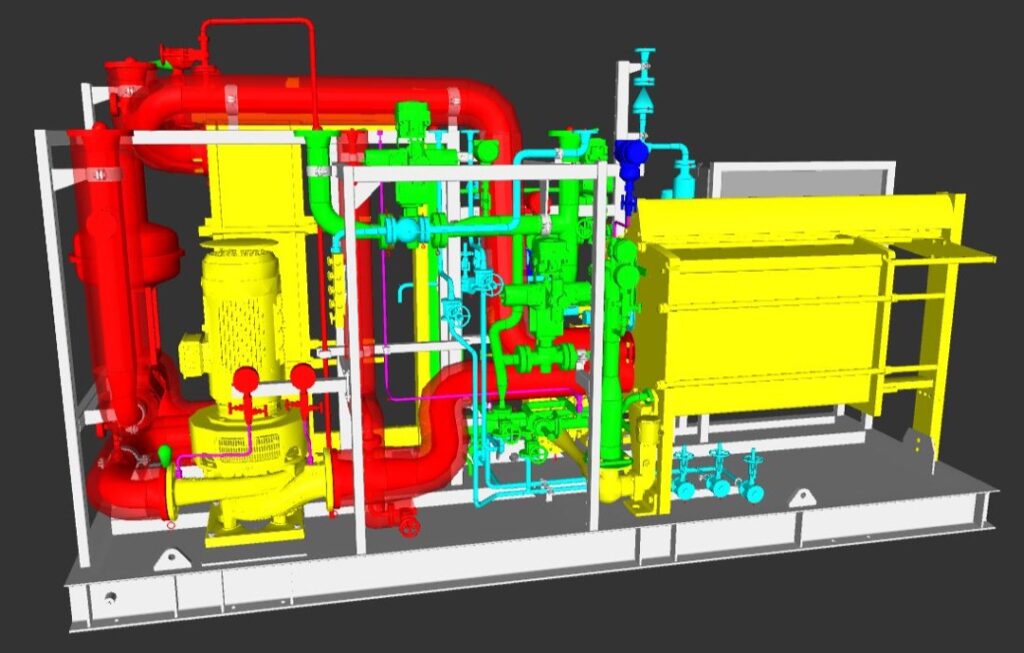

FB Group has recently supplied 3 pcs Seal Gas Conditioning Skids which will be used on high pressure compressor packages. Due to the highly corrosive nature of the gas stainless steel 316, Duplex and Incoloy 825 materials were required.

Using FB Group’s in-house developed QA/QC system full material (3.2), welding and NDE traceability has been recorded ‘live’ during fabrication and fabrication dossiers could be presented during final inspection of the units.

Another high-quality project has been successfully completed.

FB Group awarded unique CCS project: Skid mounted CO2 Treatment Unit to reduce CO2 emissions

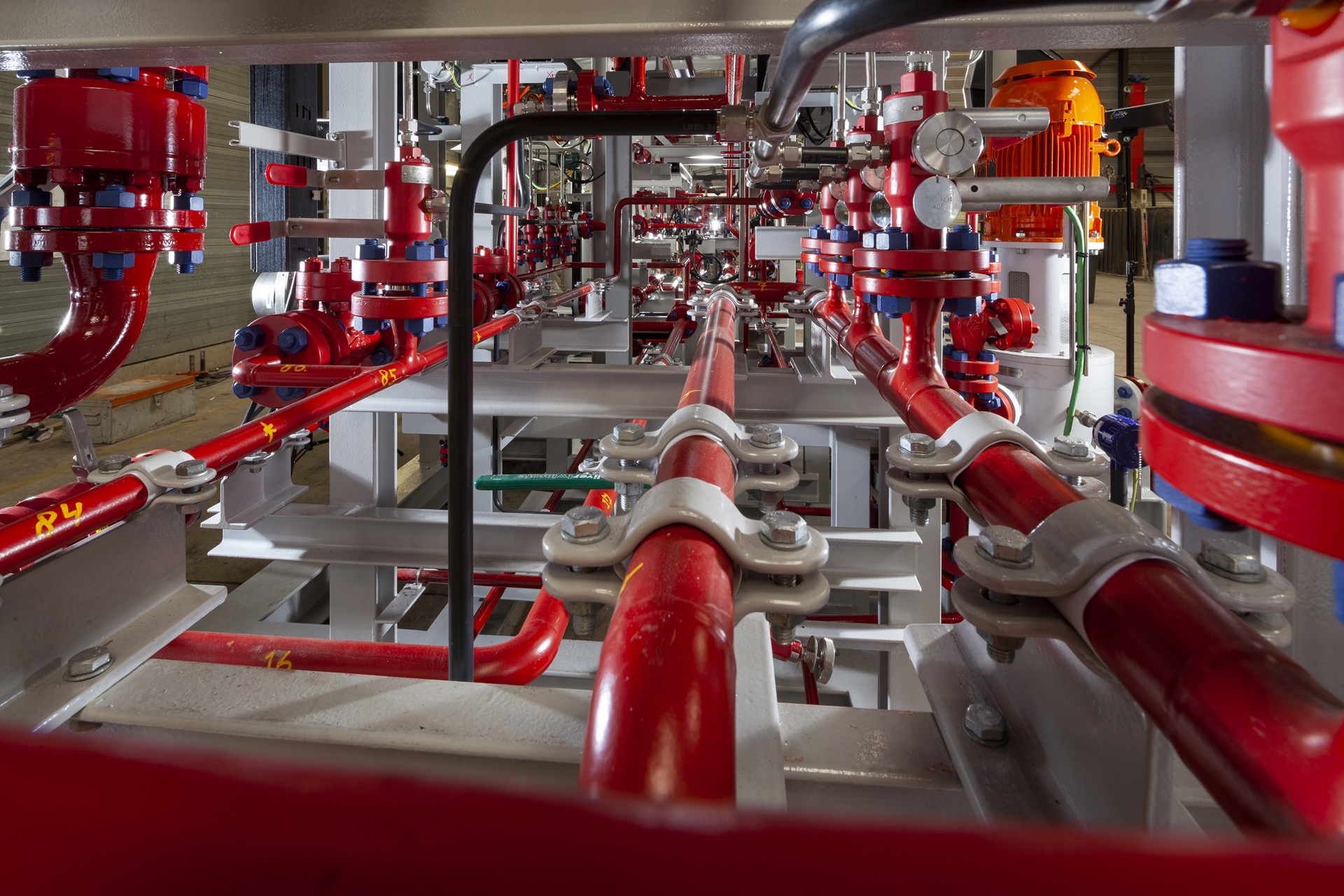

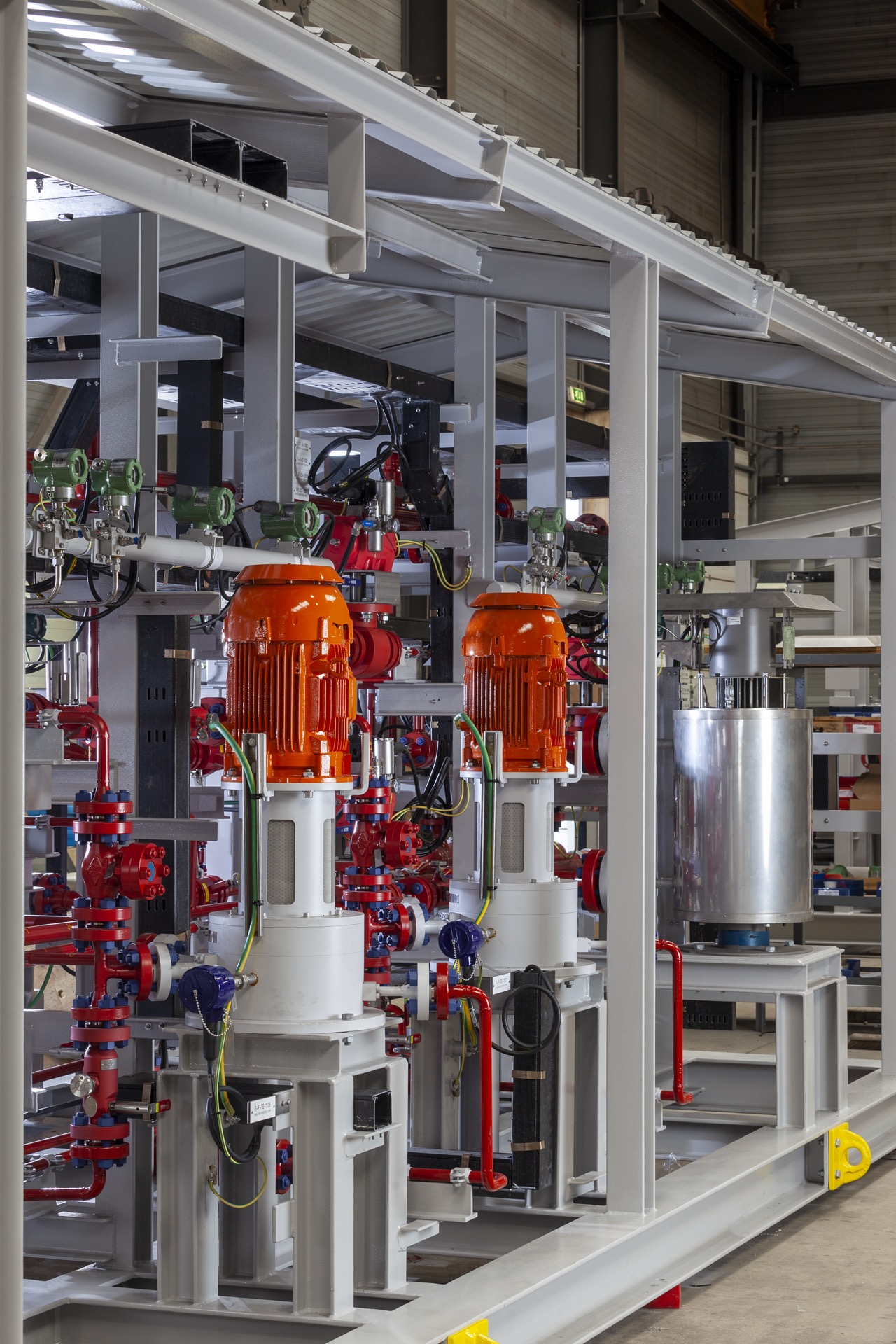

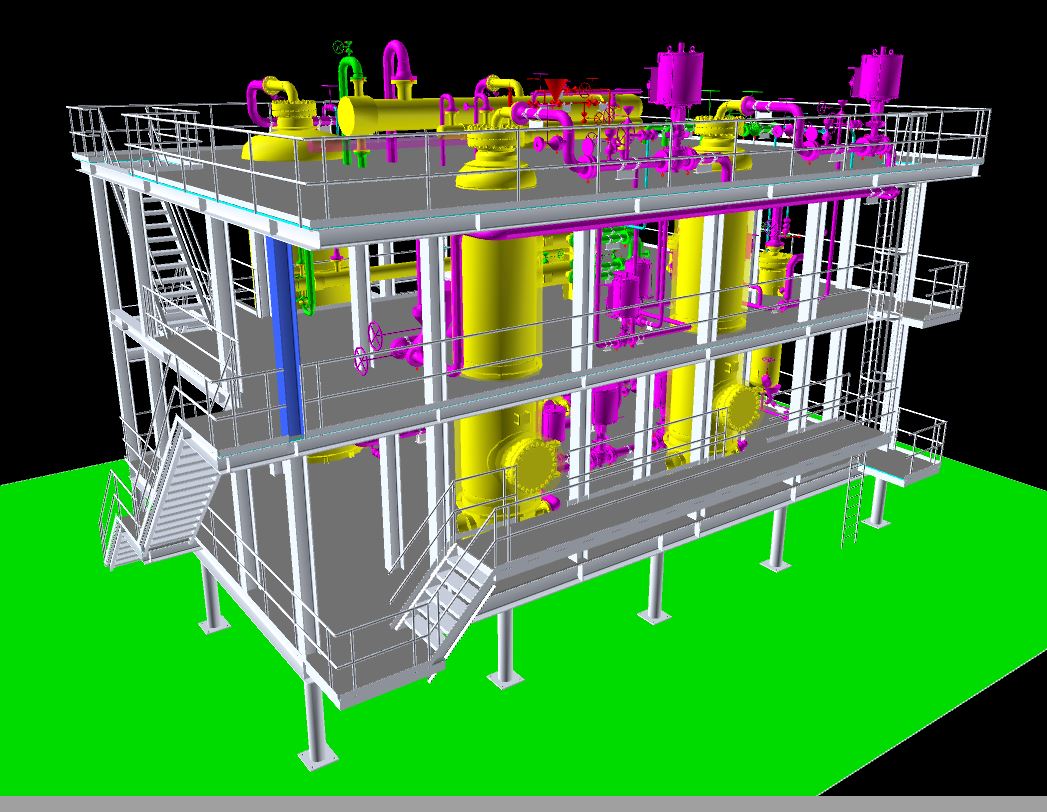

FB Group has been awarded a contract for the supply of a Modular built CO2 Conditioning Unit.

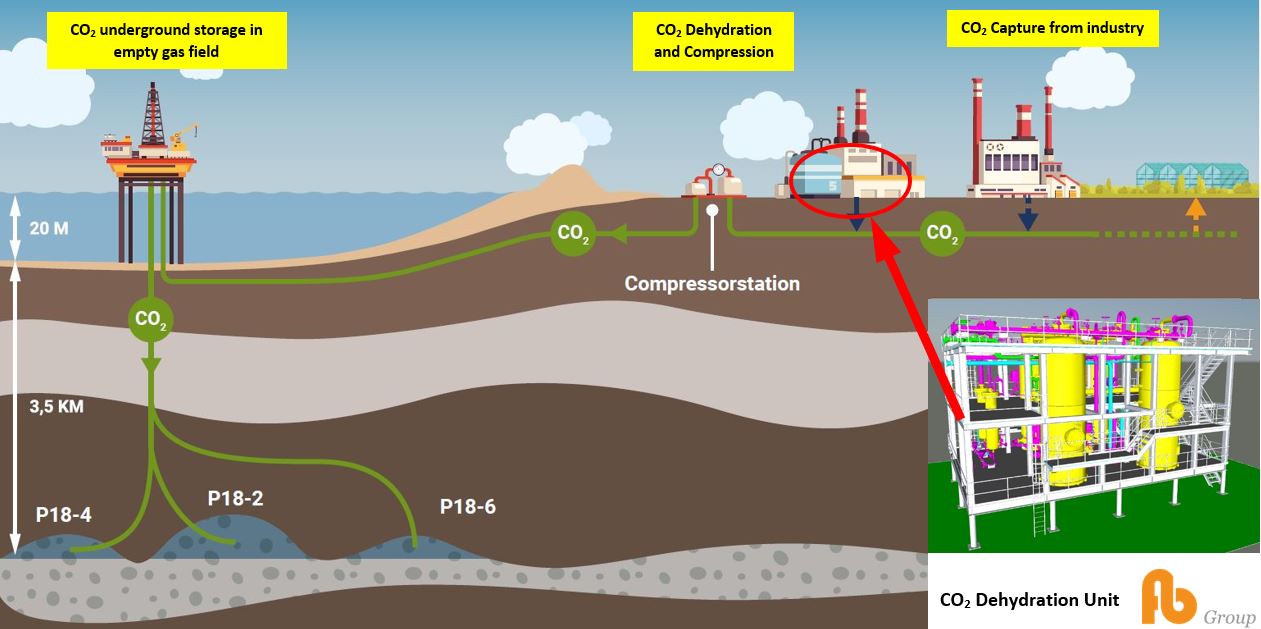

The Netherlands has clear climate objectives: the emission of Carbon Dioxide (CO2) gases shall be reduced by 55% in 2030. One way to achieve these climate objectives is to capture and store the CO₂ (CCS = Carbon Capture and Storage).

The Porthos project is developed to transport CO₂ from industry in the Port of Rotterdam and store this in empty gas fields beneath the North Sea. (Porthos stands for Port of Rotterdam CO₂ Transport Hub and Offshore Storage).

The CO2 will be transported through a pipeline to a platform in the North Sea, approximately 20 km off the coast. From this platform, the CO2 will be pumped in an empty gas field approx. 3 km depth beneath the North Sea.

Porthos will allow for storage of approx. 2.5 MegaTon CO2 per year (1 Megaton = 1.000.000.000 kg) for a period of 15 years.

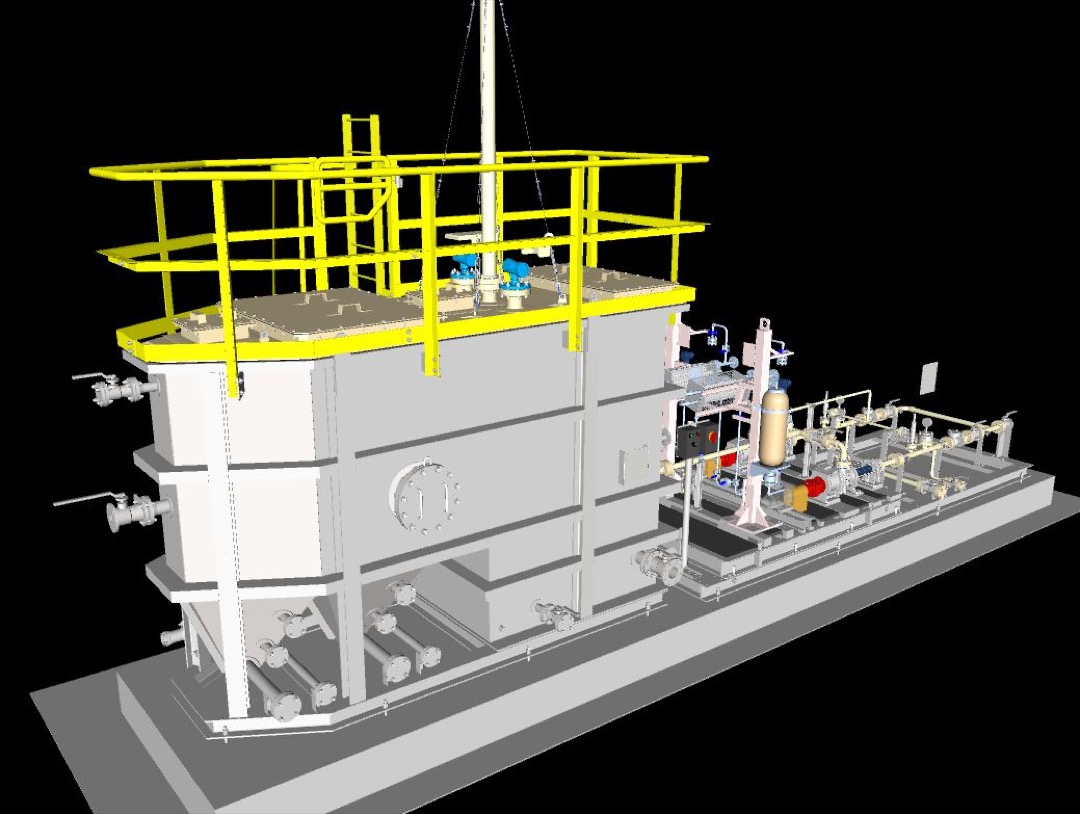

In the unit which will be supplied by FB Group, Sulphur (H2S) contaminants and water are being removed from the CO2 gas prior to being transported by pipeline. The complete module will be designed, fabricated and assembled at FB Group in Heijningen and transported to its final destination in Rotterdam area by barge (see example).

By means of this unique project FB actively contributes to less CO2 emissions and a more sustainable world.

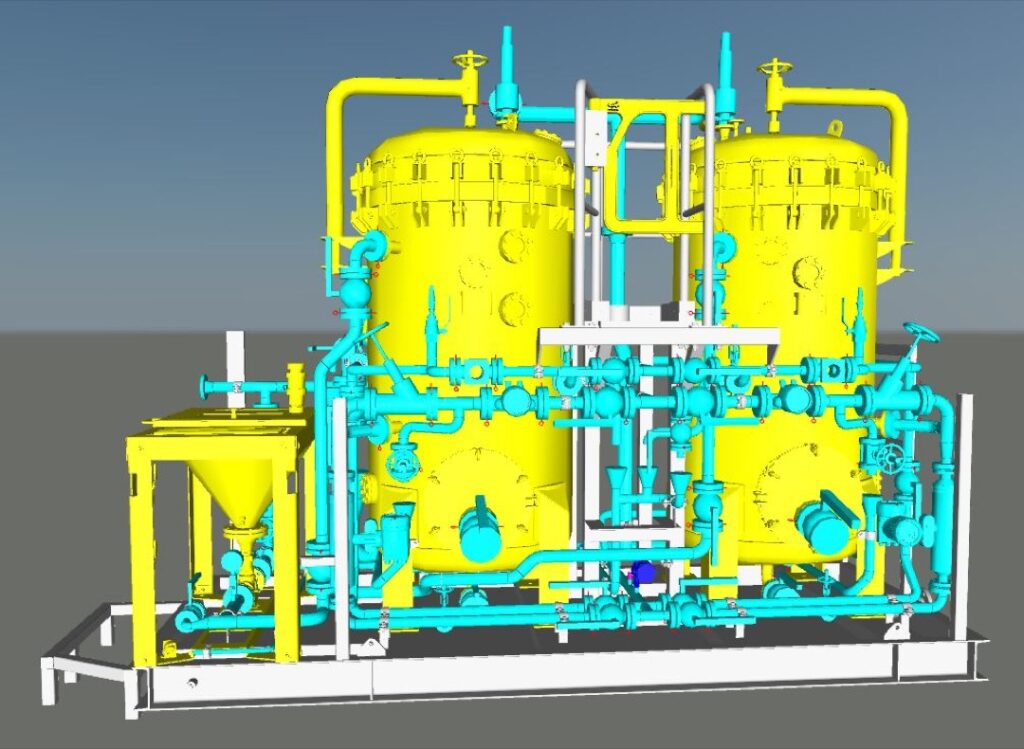

Supply of CPI Oil Separator skidmounted unit

For our valued client Pielkenrood we have fabricated a CPI (Corrugated Plate Interceptor type) Oil/Water Separator unit for treatment of wastewater at a gas processing plant in Middle East. In this type of separator oil and solids are being separated from wastewater after which the water can be safely disposed without any environmental impact.

Due to the high corrosive content of the wastewater (Chlorides and H2S) the tank received heat treatment (PWHT) to reduce stresses in materials after welding. After painting special super-duplex internals were installed to provide excellent protection against corrosion.

Another contribution to a more sustainable world…

Fabrication of Fresh Water Generation Units in progress

Recently FB Group has been awarded by Alfa Laval an order for the fabrication and supply of several skid mounted ‘Aqua units’. These units will be able to generate fresh potable or process water using seawater. The skids are being fabricated from 316 stainless steel or Titanium and will be fully tested in our workshop prior to delivery. Once completed the units will be installed on an Offshore Platform in Norwegian territorial waters. Fabrication of the units is ongoing in our workshops…

- « Previous Page

- 1

- 2

- 3

- 4

- …

- 9

- Next Page »